Forging technology

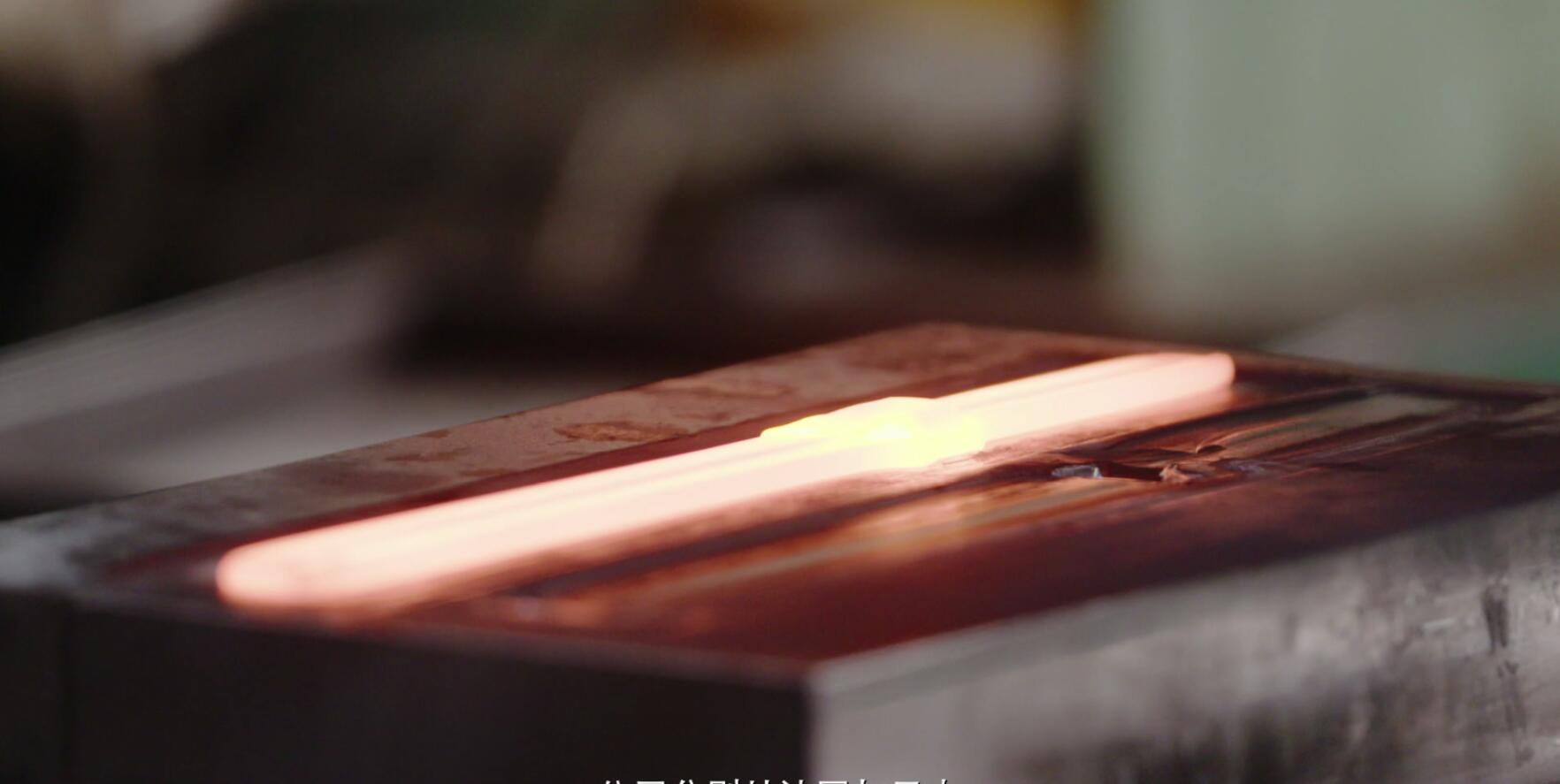

Sheaffer's forged knives accounted for 70% of its products in 2009, as demand for forged knives continues to grow That's up from 30% five years ago.This growth stems from two facts: first, more and more customers Familiar with and loyal to the real forging knife.Secondly, Sheaffer has been well received as the best real forging knife manufacturer in China More and more orders are coming in from all over the world for better real forging tools.How are real blacksmithing knives made in Sheaffer? Here's a revealing moment: take a stainless steel bar and forge it into a kitchen knife.This is the first and most refurbished production process in China since 2001. Sheaffer is now fully forged The process goes to another level, newly installed and more sophisticated hydraulic forging presses and advanced Automatic grinding machine.Sheaffer's forging process continues to produce final cost savings Increase the density of stainless steel tools after optimum forging. The reasons for this special manufacturing method are as follows: Hardness: By applying mass pressure to the steel bar, it can reach rockwell hardness of about 60 degrees after forging For the density of steel is greatly increased by this extreme force.Elasticity: Elasticity after forging Then we go through a heat treatment and ice hardening process, so we can get the elasticity we need Hardness.Both of these features have had a huge impact and provide It's a great help to the production process.

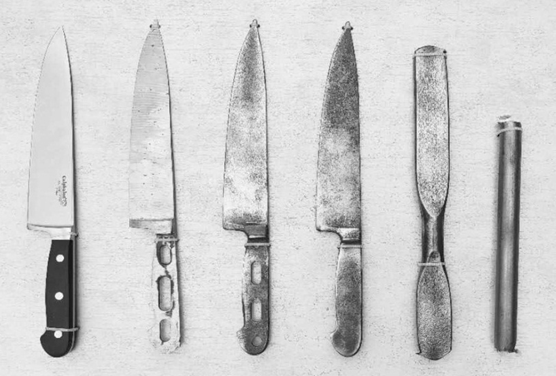

Real Forge knife

Sheaffer’s forge knife is always ‘Real Forge’From high pressure process of forge, that make knife more durable ,better balanced,more stability of the materialen hanced material density and elasticity during forging process. High stress from forge press make knife increase the intension and long in life of use.

The welding tool

Fake Forge knife -2( Welding )

Advantages of welding forged knives:

1. Cost-saving

2. Less in the process of production.

Disadvantages of welding forged knives:

1. Inferior handling

2. Material unstable around the welding parts

3. Less density and less elasticity than forged knives

4. Possibility of cracking due to instability around the knife bolster

Over heat on the welding part which make the knife easily crack and corrosion.